- Product

- fire engine

- New energy vehicle

- Sprinkler

- Dust suppression vehicle

- Sewage suction truck

- fire engine

- Fecal suction truck

- Road sweeper

- Washing and sweeping vehicle

- High pressure cleaning vehicle

- Kitchen garbage truck

- Cleaning suction truck

- Road clearing vehicle

- garbage dump truck

- Swing arm garbage truck

- Docking garbage truck

- Compression type garbage truck

- Mobile compressed garbage station

- Hook arm garbage truck

- Truck with crane

- Platform car

-

- Personnel carrier

- hydraulic aerial cage

-

-

-

-

-

HOME > Product > fire engine >

XZL5171GXFPM70/E6 foam fire truck

XZL5171GXFPM70/E6 foam fire truck

Technical specifications

Hubei Xinzhonglv Special Vehicle Co., Ltd

No. 8, Liangshui Industrial Zone, Suizhou City

1. Overview

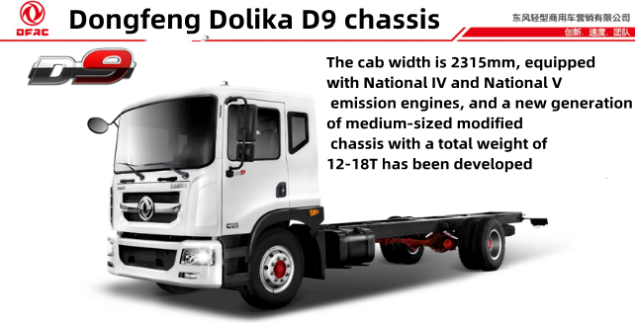

The XZL5171GXFSG70/E6 water tank fire truck is modified from the Dongfeng EQ1185DJ9CDF chassis. The whole vehicle consists of two main parts: the firefighter's cabin and the vehicle body. The cabin is original double row and can accommodate 3+3 people. The vehicle has a hidden tank structure, with equipment boxes on both sides of the body, a tank body in the middle, and a pump room at the rear. The liquid tank body is made of high-quality carbon steel, with epoxy primer and epoxy asphalt paint sprayed on the inside. It is elastically connected to the chassis and has a water carrying capacity of 7150kg. It is equipped with the CB10/40-RS atmospheric fire pump produced by Shanghai Rongshen Fire Equipment Co., Ltd., with a rated flow rate of 40L/S. The roof is equipped with the PL32 vehicle fire monitor produced by Chengdu West Fire Machinery Co., Ltd. The biggest feature of this car is its large liquid carrying capacity, good handling, and easy maintenance. It can be widely used in public security fire brigades, factories, mining enterprises, communities, docks and other places to extinguish large oil fires and general material fires. The fire performance of the entire vehicle meets the requirements of GB7956-2014 standard; The chassis has passed the national mandatory product certification; The engine emissions comply with the requirements of the sixth stage limit of GB17691-2018 National VI; The entire vehicle has passed the inspection by the National Fire Equipment Quality Supervision and Inspection Center (report number: Zb202030265) and has been listed in the Ministry of Industry and Information Technology's announcement of new automotive products. |

2. Main parameters of the entire vehicle

Overall dimensions | 8510×2550×3560mm |

Maximum total mass | 16800kg |

Liquid carrying capacity | Water tank carrying water 7150kg |

maximum speed | 95km/h |

Rated flow rate of fire pump | 40L/s 1.0MPa |

Rated flow rate of fire monitor | 40L/s 1.0MPa |

Fire cannon range | ≥65m |

specific power | 169/16.8=10.1 |

Approach/departure angle | 19°/12° |

Chassis

1、Parameters

model | EQ1185DJ9CDF |

manufacturer | Dongfeng Motor Co., Ltd |

Engine power rating | 169kw 230horsepower |

Displacement | 6200ml |

Engine emission standards | GB3847-2005,GB17691-2018 National VI |

Driving form | 4×2 |

wheelbase | 4700mm |

Maximum allowable total weight | 17400g |

Transmission | hand movement |

2、Passenger compartment

structure | Flat head, four doors, original double row |

|

Number of drivers and passengers | 3+3people | |

Driver's position | Right placement | |

device | Install fire operation instrument panel and alarm light control box at the original vehicle dashboard, and add 1. Alarm; 2. Power take-off control switch and indicator light; 3. Additional power switch; |

Upper structure and performance parameters

Overall layout | The whole vehicle consists of two main parts: the firefighter's cabin and the vehicle body. The body layout adopts a three part structure, with equipment boxes on both sides, water tanks in the middle, and a water pump room at the rear. The tank body is a parallelepiped box type container |

| |

Equipment box and pump room

structure | The main frame structure is welded with high-quality square tubes, and the outer decorative panel is welded with carbon steel plates. The roof is non slip and walkable, with flipping pedals on both sides and anti slip design. (Aluminum alloy square tube welding can be used according to user needs) |

|

Equipment box | The equipment box is located at the rear of the passenger compartment, with aluminum alloy rolling shutter doors on both sides and lighting inside. Install storage boxes inside the equipment box according to needs. The side skirt is equipped with a toolbox and a rolling shutter door, which can accommodate small tools | |

pump house | The pump room is located at the rear of the vehicle, with aluminum alloy rolling shutter doors on both sides and at the rear. There are lighting lights inside, and some commonly used equipment can be placed on both sides of the pump room Install fuel heater (optional according to customer requirements) | |

Ladder climbing and boarding handle | The rear climbing ladder is made of aluminum alloy with two flipped sections. When used, the height from the ground should not exceed 350mm. The handle for getting on the car is made of anti slip round steel pipes with grooves on the surface, and the surface is sprayed with plastic. | |

Water tank | ||

capacity | 5300kg(PM70),7150kg(SG70) |

|

material quality | The foam tank is made of high-quality stainless steel High quality carbon steel, with a thickness of 5mm for the bottom plate, 4mm for the side plate, and 4mm for the top plate | |

Tank body fixation | Elastic connection with chassis frame | |

Can body settings | Manhole: One DN460 manhole with quick locking/opening automatic pressure relief device | |

Overflow port: Install one DN40 overflow port | ||

Drain outlet: Install one DN25 water tank drain outlet with ball valve | ||

Water inlet: Connect one DN65 interface on each side of the water tank | ||

Inlet and outlet: One water tank to water pump inlet pipe DN125 valve for manual control (pneumatic optional), and one water pump to water tank filling pipe DN65 valve for manual control (pneumatic optional) | ||

Foam tank

capacity | 1850kg(PM70) |

|

material quality | High quality stainless steel, with a thickness of 5mm for the bottom plate, 4mm for the side plate, and 4mm for the top plate | |

Tank body fixation | Elastic connection with chassis frame | |

Can body settings | Manhole: One DN460 manhole with quick locking/opening and automatic pressure relief device | |

Overflow port: Install one DN40 overflow port | ||

Drain port: Install one DN25 drain port with ball valve | ||

Foam suction port: one DN40 foam tank to foam outlet pipe of water pump |

Water system

1、water pump

model | CB10/40 atmospheric pressure vehicle fire pump |

|

form | Atmospheric centrifugal | |

Rated flow rate | 40L/s @1.0MPa | |

Rated outlet pressure | 1.0MPa | |

Maximum suction depth | 7m | |

priming device | Equipped with sliding vane pump | |

Diversion time | Maximum suction depth ≤ 50s |

2、 Pipeline system

Pipe Material | High quality seamless steel pipe | |

Water suction pipeline | Install one DN125 suction port on each side of the pump room | |

Water injection pipeline | One DN65 water inlet is installed on both sides of the water tank, and one DN65 water pump is installed in the pump room to inject water into the tank | |

Water outlet pipeline | One DN80 water outlet is installed on both sides of the pump room, equipped with a shut-off valve and a cover | |

Cooling water pipeline | Cooling water pipeline and control valve equipped with cooling power take-off |

Fire extinguishing equipment

Foam monitor (PM70)

model | PL8/32 |

|

manufacturer | Chengdu West Fire Machinery Co., Ltd | |

ROTATION | 360°Horizontal rotation | |

Maximum pitch/pitch angle | Depression angle ≤ -15 °, elevation angle ≥+45 ° | |

flow | 32L/S | |

range | Foam ≥ 48m Water ≥ 60m |

Water cannon (SG70)

model | PS40W |

|

manufacturer | Chengdu West Fire Machinery Co., Ltd | |

ROTATION | 360°Horizontal rotation | |

Maximum pitch/pitch angle | Depression angle ≤ -15 °, elevation angle ≥+45 ° | |

flow | 40L/S | |

range | Water≥65m |

Fire control system

The control panel mainly includes two parts: cab control and pump room control

Control inside the cab | Pump disengagement, alarm lights, lighting and signal device control, etc |

|

Pump room control | Upper main power switch, parameter display, status display |

Electrical equipment

Additional Electrical | Set up independent circuits |

|

Auxiliary lighting | The firefighter's room, water pump room, and equipment box are respectively equipped with lighting lights, and the control dashboard is equipped with lighting, indicator lights, etc | |

Strobe light | Install red and blue strobe lights on both sides of the vehicle body | |

Warning device | Long row all red warning lights, installed on the top of the cab | |

Alarm, with its control box located below the driver's front | ||

incident lighting | Install one 35W fire searchlight at the rear of the upper part |

Surface treatment

finish | High quality domestic paint |

colour | Spray according to requirements |

Layout and equipping of on-board firefighting equipment

1、Equipment layout

1 | According to the actual needs of fire fighting and according to the fire operation procedures, take and place them nearby. |

2 | Fix with specialized fixtures that prevent rust, vibration, detachment, and scratches. |

3 | Clearly marked, operated by multiple people, non-interference with each other。 |

2、Equipment configuration (standard model reference, specific model to be determined along with the vehicle)

1 | suction | 2 | root | Threaded type |

2 | water filter | 1 | piece | Threaded type |

3 | Water separator | 1 | piece | Internal buckle type |

4 | Catcher | 1 | piece | Internal buckle type |

5 | Water belt | 6 | tray | Internal buckle type |

6 | Water belt | 6 | tray | Internal buckle type |

7 | increaser | 2 | piece | Internal buckle type |

8 | hose bandage | 4 | piece | |

9 | Water hose hook | 4 | piece | |

10 | Ground fire hydrant wrench | 1 | piece | |

11 | Underground fire hydrant wrench | 1 | piece | |

12 | Water suction pipe wrench | 2 | piece | |

13 | DC switch water gun | 1 | count | Internal buckle type |

14 | DC flowering water gun | 1 | count | Internal buckle type |

15 | Foam gun | 1 | count | |

16 | Foam pipette | 1 | piece | |

17 | Fire Bucket | 1 | count | |

18 | Fire Extinguisher | 1 | count | |

19 | Firefighting waist axe | 1 | piece | |

20 | Rubber Hammer | 1 | piece | |

21 | Rechargeable portable lighting | 1 | piece |

Optional configuration and equipment

1 | Automatic charging device | 24V | 1 | set | |

2 | Air breathing backrest | 3 | set | ||

3 | Air respirator | Number of members | set | ||

4 | Water belt bridge protection | rubber | 2 | individual | |

5 | Telescopic ladder | 1 | individual | ||

6 | Hand pump | 1 | tower | ||

7 | breaking-in tool | 1 | set | ||

8 | Other fire-fighting equipment |

中文

中文 EN

EN